While I do not have all the tools to review and comment on or post. I have pretty much all of them.

Buck, if you want to take a picture of your tool and post it. I have gotten to use it and try it out. Buck uses the block.

Now- before I even begin.

Note: this is not a debate topic, not a pick which is better topic, Not knock a product. It's about showing tools, options and maybe some mild comments. From a Scout and parent perspective.

I am not endorsing any product or excluding a product.

These are some of what I have worked with. I do not know which ones all came out first or 2nd or last, does not matter.

First up-

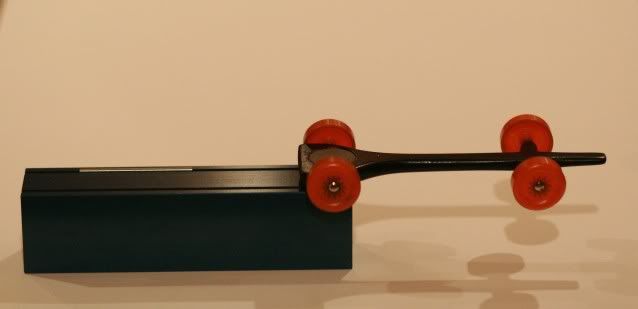

The pro body tool.

When it first came out, it helped scouts go from nothing to something, being able to use.

It gave kids and parents and workshop people a low cost way to drill axle wholes.

It was a improvment at a low cost.

Then came the pro body jig along.

It offers stability with adjustability.

Next up is something common we can use with little cost.

Another block of wood and a gauge pin or dril blank or drill rod and clamps.

Here is a tool, I had made for me.

I took some design idieas from one tool and my own ideas to come up with this-

A adjustable axle whole canting. insert or remove different bushings, that have different degrees. Also different size wholes for different drill bits. by changing out the bushings. It's a bit crued but a proto-type of mine.

adjustable angle block.

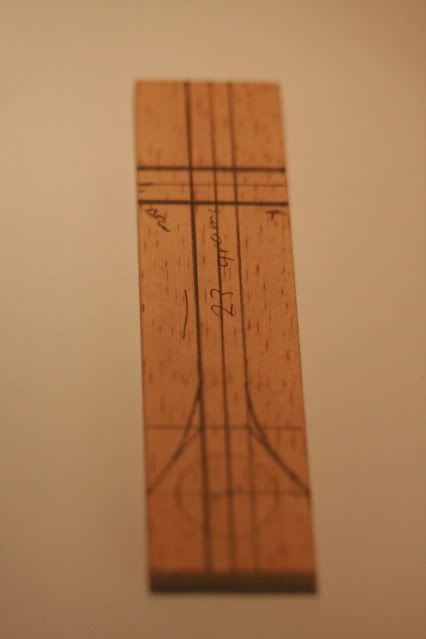

I had been looking for awhile for a adjustable block and one day, quadad found what I was looking for on e-bay.

It has degrees and can be adjusted and its been around awhile.

There our more tools out there, more to be made and better and easier ways all around that come about.

It is a buyer and builder prefrenece to what you use.

Again, I have tried the block and would post pictures, But I do not own one. Perhaps buck or someone will post a pic of there tool.