Revisiting bent rear axles

- LightninBoy

- Master Pine Head

- Posts: 203

- Joined: Mon Feb 20, 2012 9:09 pm

- Location: St. Paul, MN

Re: Revisiting bent rear axles

I drill my rears canted instead of bending axles. I don't do it because I think its faster in and of itself. I do it because its repeatable and removes a variable, particularly since the cub scout council rules and the leagues I race in allow aftermarket axles. This has allowed me to more easily experiment and compare various setups, techniques, and products without having to worry that the difference may actually be due to a slight change in the bent axle alignment. This has in turn enabled me to find speed - and just as important - know what doesn't give me speed.

- FatSebastian

- Pine Head Legend

- Posts: 2818

- Joined: Wed Jun 17, 2009 2:49 pm

- Location: Boogerton, PA

Re: Revisiting bent rear axles

I agree that time-saving aspects are important for children's racing. Kids have limited patience, and tasks that start to seem like drudgery or require too much finesse can quickly rob them of enthusiasm.LightninBoy wrote:I do it because its repeatable and removes a variable, particularly since the cub scout council rules and the leagues I race in allow aftermarket axles.

Re: Revisiting bent rear axles

So this raises another question in my mind: Does straight axles alignment become more advantageous when aftermarket axles are allowed?LightninBoy wrote:I drill my rears canted instead of bending axles. I don't do it because I think its faster in and of itself. I do it because its repeatable and removes a variable, particularly since the cub scout council rules and the leagues I race in allow aftermarket axles. This has allowed me to more easily experiment and compare various setups, techniques, and products without having to worry that the difference may actually be due to a slight change in the bent axle alignment. This has in turn enabled me to find speed - and just as important - know what doesn't give me speed.

For one, if you can be assured of the straightness of your axles, that removes one pain point, at least.

Re: Revisiting bent rear axles

We made a rail-runner for the first time last year and bent our stock BSA kit axles. We bent them so very little that I had to put them in a drill and look at the head from the top as it spun in order to see the bend. Once we got them aligned I erased the black marker on the head and used an engraver to mark the new 12:00 position. We also re-prepped after every event which meant extra tuning time.

For us, bending the axles meant not having to buy perfectly straight axles. If you drill canted then they have to be absolutely perfect holes (zero toe). Even the straightest appearing stock kit axle will have a slight bend that you can't see which makes using them with canted holes would most likely require tuning anyways.

For us, bending the axles meant not having to buy perfectly straight axles. If you drill canted then they have to be absolutely perfect holes (zero toe). Even the straightest appearing stock kit axle will have a slight bend that you can't see which makes using them with canted holes would most likely require tuning anyways.

Re: Revisiting bent rear axles

Can you avoid the cost of the Block by just drilling canted holes with a fence. Get the drill bit perfectly vertical then place your block of wood on the table and put a level across the top of the wood where you'll be drilling. Level that front to back and side to side. This should give you a perfect hole even if the wood block isn't perfectly square. Does that make sense? That's where The Block works well is when the wood block isn't perfectly square.

Re: Revisiting bent rear axles

My method in the past was to use the fence-and-spacer technique on the drill press. I don't use a level, because I'm not convinced that the drill press table itself perfectly level. Instead, I would check for squareness of the drill press platform with the bit, squareness of the fence block, and squareness of the block being drilled. It worked "okay", in that I could get a drilled set that appeared visually straight and would run straight down a ramp, if I tried enough times. Success rate was well below 50%, though.

davet wrote:Can you avoid the cost of the Block by just drilling canted holes with a fence. Get the drill bit perfectly vertical then place your block of wood on the table and put a level across the top of the wood where you'll be drilling. Level that front to back and side to side. This should give you a perfect hole even if the wood block isn't perfectly square. Does that make sense? That's where The Block works well is when the wood block isn't perfectly square.

Re: Revisiting bent rear axles

Did you say you use the Block now? What is your success rate with that?Vitamin K wrote:My method in the past was to use the fence-and-spacer technique on the drill press. I don't use a level, because I'm not convinced that the drill press table itself perfectly level. Instead, I would check for squareness of the drill press platform with the bit, squareness of the fence block, and squareness of the block being drilled. It worked "okay", in that I could get a drilled set that appeared visually straight and would run straight down a ramp, if I tried enough times. Success rate was well below 50%, though.

davet wrote:Can you avoid the cost of the Block by just drilling canted holes with a fence. Get the drill bit perfectly vertical then place your block of wood on the table and put a level across the top of the wood where you'll be drilling. Level that front to back and side to side. This should give you a perfect hole even if the wood block isn't perfectly square. Does that make sense? That's where The Block works well is when the wood block isn't perfectly square.

Re: Revisiting bent rear axles

I was ready to buy the Block, but I'm going to go with bent axles this Derby season. I'll definitely report back on our success aligning/tuning/running.davet wrote:Did you say you use the Block now? What is your success rate with that?Vitamin K wrote:My method in the past was to use the fence-and-spacer technique on the drill press. I don't use a level, because I'm not convinced that the drill press table itself perfectly level. Instead, I would check for squareness of the drill press platform with the bit, squareness of the fence block, and squareness of the block being drilled. It worked "okay", in that I could get a drilled set that appeared visually straight and would run straight down a ramp, if I tried enough times. Success rate was well below 50%, though.

Re: Revisiting bent rear axles

If you have the drill bit square and a level across the top of the block shows level then it should be good. If the drill press table isn't level then lay block on the table and square the drilling surface of block up to the bit. The table the press is resting on could be at 30 degree angle but if you square the block to the bit then it's perfect.Vitamin K wrote:My method in the past was to use the fence-and-spacer technique on the drill press. I don't use a level, because I'm not convinced that the drill press table itself perfectly level. Instead, I would check for squareness of the drill press platform with the bit, squareness of the fence block, and squareness of the block being drilled. It worked "okay", in that I could get a drilled set that appeared visually straight and would run straight down a ramp, if I tried enough times. Success rate was well below 50%, though.

davet wrote:Can you avoid the cost of the Block by just drilling canted holes with a fence. Get the drill bit perfectly vertical then place your block of wood on the table and put a level across the top of the wood where you'll be drilling. Level that front to back and side to side. This should give you a perfect hole even if the wood block isn't perfectly square. Does that make sense? That's where The Block works well is when the wood block isn't perfectly square.

- Stan Pope

- Pine Head Legend

- Posts: 6856

- Joined: Sat Jul 05, 2003 7:01 pm

- Location: Morton, Illinois

- Contact:

Re: Revisiting bent rear axles

I'm so happy to be back on DT!!! For about a month, there was a foul-up on the path between here and DT that (most of the time) prevented me from participating. Randy has gotten it resolved!!!

So, maybe those who claim that "there is no possible way" should rephrase their claim to "I don't know how to"!

Rear axle alignment with bent axles on a small alignment board (to the degree that on-track tweaking of either rear axle gives no improvement) is, at most, a 15 minute job for a beginner and more like 5 minutes after practice. More than once, I've pointed to the method that I use. There may be faster methods, but it is hard to beat 5 minutes!Vitamin K wrote:Of course, I have seen some claim that it is "impossible" to tune bent-wheel alignment properly. Hyperbole? Or is the claim that there's just no possible way to get bent axle rears to be aligned as well as drilled-cant rears?

So, maybe those who claim that "there is no possible way" should rephrase their claim to "I don't know how to"!

Stan

"If it's not for the boys, it's for the birds!"

"If it's not for the boys, it's for the birds!"

- Stan Pope

- Pine Head Legend

- Posts: 6856

- Joined: Sat Jul 05, 2003 7:01 pm

- Location: Morton, Illinois

- Contact:

Re: Revisiting bent rear axles

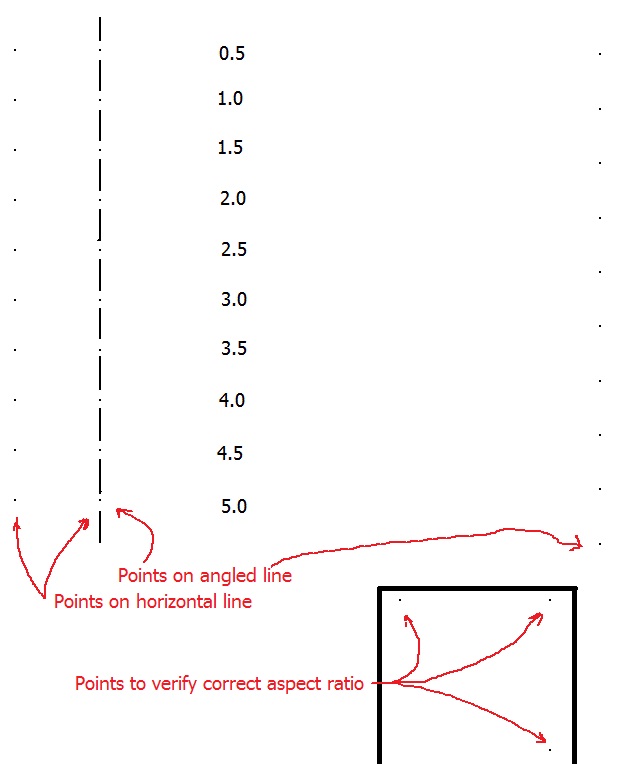

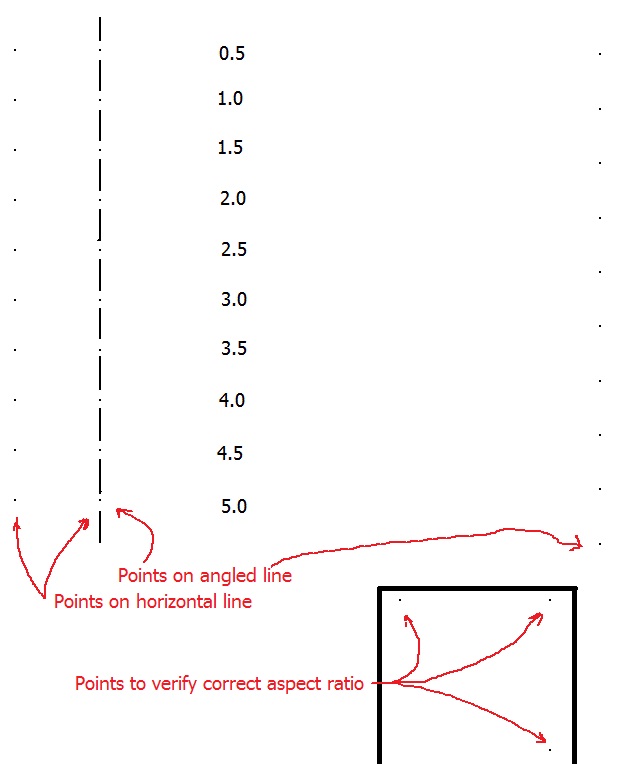

Here is a trial method for estimating axle bend angles. Some folks to test and critique will be appreciated.

Here is a printable .bmp file to guide drawing various bend angles. Download and connect the dots!

I tried drawing the lines by the computer, but the image is too pixelated. So, instead, I give an image on which you can draw smooth, straight, non-pixlelated lines.

Here is how I finish the Gage:

1. Download and print AxleBendGage.bmp.

2. Check that the dots in the box in the lower right are equidistant. Sometimes different renderings of graphics files differ in aspect ratio, which means that horizontal and vertical spacing of pixels are different. If the horizontal separation differs from the vertical separation, then we need to try a different rendering.

3. If the aspect ratio is 1:1, then the angles formed by the various dot triples will be true, and you can continue. Otherwise, try to alter the aspect ratio to 1:1.

4. Each angle is formed by a horizontal line (left pair of dots), and an angled line (right pair of dots). The center dots are in common. Connect the left pair of dots at the top of the drawing. Find the corresponding dot on the right side and connect the center dot to it. Be careful to draw the lines straight and well centered on the dots. A 1 pixel error in positioning the lines will create an error of about 1/8 of a degree! Care is essential.

5. Repeat connecting the dots for the remainder of the dot triples.

How to use the gage:

1. Identify the side of the bent axle that will contact the wheel bore.

2. Compare that side of the bent axle to the various lines, looking for the sides to correspond on each side of the common point (apex). Don't try to get the nail bend point to lie on the apex ... the bend is not sharp enough. Instead look at the straight parts of the axle.

Here is an image with notes:

Here is a printable .bmp file to guide drawing various bend angles. Download and connect the dots!

I tried drawing the lines by the computer, but the image is too pixelated. So, instead, I give an image on which you can draw smooth, straight, non-pixlelated lines.

Here is how I finish the Gage:

1. Download and print AxleBendGage.bmp.

2. Check that the dots in the box in the lower right are equidistant. Sometimes different renderings of graphics files differ in aspect ratio, which means that horizontal and vertical spacing of pixels are different. If the horizontal separation differs from the vertical separation, then we need to try a different rendering.

3. If the aspect ratio is 1:1, then the angles formed by the various dot triples will be true, and you can continue. Otherwise, try to alter the aspect ratio to 1:1.

4. Each angle is formed by a horizontal line (left pair of dots), and an angled line (right pair of dots). The center dots are in common. Connect the left pair of dots at the top of the drawing. Find the corresponding dot on the right side and connect the center dot to it. Be careful to draw the lines straight and well centered on the dots. A 1 pixel error in positioning the lines will create an error of about 1/8 of a degree! Care is essential.

5. Repeat connecting the dots for the remainder of the dot triples.

How to use the gage:

1. Identify the side of the bent axle that will contact the wheel bore.

2. Compare that side of the bent axle to the various lines, looking for the sides to correspond on each side of the common point (apex). Don't try to get the nail bend point to lie on the apex ... the bend is not sharp enough. Instead look at the straight parts of the axle.

Here is an image with notes:

Stan

"If it's not for the boys, it's for the birds!"

"If it's not for the boys, it's for the birds!"

- Stan Pope

- Pine Head Legend

- Posts: 6856

- Joined: Sat Jul 05, 2003 7:01 pm

- Location: Morton, Illinois

- Contact:

Re: Revisiting bent rear axles

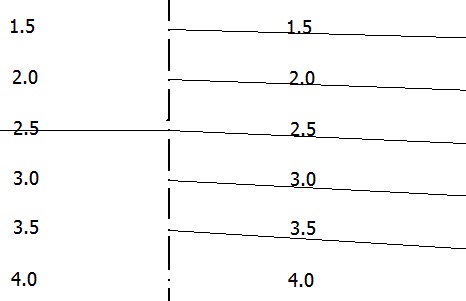

Here is version 2 of a trial method for estimating axle bend angles. Some folks to test and critique will be appreciated.

Here is a printable .bmp file to guide drawing various bend angles. Download and connect the dots!

I tried drawing the lines by the computer, but the image is too pixelated.

Here is an image showing pixelation:

So, instead, I give an image on which you can draw smooth, straight, non-pixlelated lines.

Here is how I finish the Gage:

1. Download and print AxleBendGageV2.bmp.

2. Check that the dots in the box in the lower right are equidistant. The distance from points x to y must be the same as the distance from points y to z. Sometimes different renderings of graphics files differ in aspect ratio, which means that horizontal and vertical spacing of pixels are different. If the horizontal separation differs from the vertical separation, then we need to try a different rendering.

3. If the aspect ratio is 1:1, then the angles formed by the various dot triples will be true, and you can continue. Otherwise, try to alter the aspect ratio to 1:1.

4. Each angle is formed by a horizontal line (dot from column A to dot from column B) and an angled line (dot from column B to dot from column C). Connect the left pair of dots at the top of the drawing. Find the corresponding dot on the right side and connect the center dot to it. Be careful to draw the lines straight and well centered on the dots. A 1 pixel error in positioning the lines will create an error of about 1/8 of a degree! Care is essential.

5. Repeat connecting the dots for the remainder of the dot triples.

How to use the gage:

1. Identify the side of the bent axle that will contact the wheel bore.

2. Compare that side of the bent axle to the various lines, looking for the sides to correspond on each side of the common point (apex). Don't try to get the nail bend point to lie on the apex ... the bend is not sharp enough. Instead look at the straight parts of the axle.

Here is a printable .bmp file to guide drawing various bend angles. Download and connect the dots!

I tried drawing the lines by the computer, but the image is too pixelated.

Here is an image showing pixelation:

So, instead, I give an image on which you can draw smooth, straight, non-pixlelated lines.

Here is how I finish the Gage:

1. Download and print AxleBendGageV2.bmp.

2. Check that the dots in the box in the lower right are equidistant. The distance from points x to y must be the same as the distance from points y to z. Sometimes different renderings of graphics files differ in aspect ratio, which means that horizontal and vertical spacing of pixels are different. If the horizontal separation differs from the vertical separation, then we need to try a different rendering.

3. If the aspect ratio is 1:1, then the angles formed by the various dot triples will be true, and you can continue. Otherwise, try to alter the aspect ratio to 1:1.

4. Each angle is formed by a horizontal line (dot from column A to dot from column B) and an angled line (dot from column B to dot from column C). Connect the left pair of dots at the top of the drawing. Find the corresponding dot on the right side and connect the center dot to it. Be careful to draw the lines straight and well centered on the dots. A 1 pixel error in positioning the lines will create an error of about 1/8 of a degree! Care is essential.

5. Repeat connecting the dots for the remainder of the dot triples.

How to use the gage:

1. Identify the side of the bent axle that will contact the wheel bore.

2. Compare that side of the bent axle to the various lines, looking for the sides to correspond on each side of the common point (apex). Don't try to get the nail bend point to lie on the apex ... the bend is not sharp enough. Instead look at the straight parts of the axle.

Stan

"If it's not for the boys, it's for the birds!"

"If it's not for the boys, it's for the birds!"

Re: Revisiting bent rear axles

This looks quite useful, Stan! I thought it might helpful, so I went ahead and filled in the lines and have created a printable PDF which should keep all aspect ratios correct.Stan Pope wrote:Here is version 2 of a trial method for estimating axle bend angles. Some folks to test and critique will be appreciated.

Here is a printable .bmp file to guide drawing various bend angles. Download and connect the dots!

I tried drawing the lines by the computer, but the image is too pixelated.

- Stan Pope

- Pine Head Legend

- Posts: 6856

- Joined: Sat Jul 05, 2003 7:01 pm

- Location: Morton, Illinois

- Contact:

Re: Revisiting bent rear axles

Good! You got rid of some of the pixilation. Does it hold through printing? (It looked good on my laser printer.)Vitamin K wrote:This looks quite useful, Stan! I thought it might helpful, so I went ahead and filled in the lines and have created a printable PDF which should keep all aspect ratios correct.Stan Pope wrote:Here is version 2 of a trial method for estimating axle bend angles. Some folks to test and critique will be appreciated.

Here is a printable .bmp file to guide drawing various bend angles. Download and connect the dots!

I tried drawing the lines by the computer, but the image is too pixelated.

Stan

"If it's not for the boys, it's for the birds!"

"If it's not for the boys, it's for the birds!"

Re: Revisiting bent rear axles

Yep! Any modern printer with a decent resolution should print out a nice rendering. No promises if you still have a dot-matrix, though.Stan Pope wrote:Good! You got rid of some of the pixilation. Does it hold through printing? (It looked good on my laser printer.)Vitamin K wrote:

This looks quite useful, Stan! I thought it might helpful, so I went ahead and filled in the lines and have created a printable PDF which should keep all aspect ratios correct.